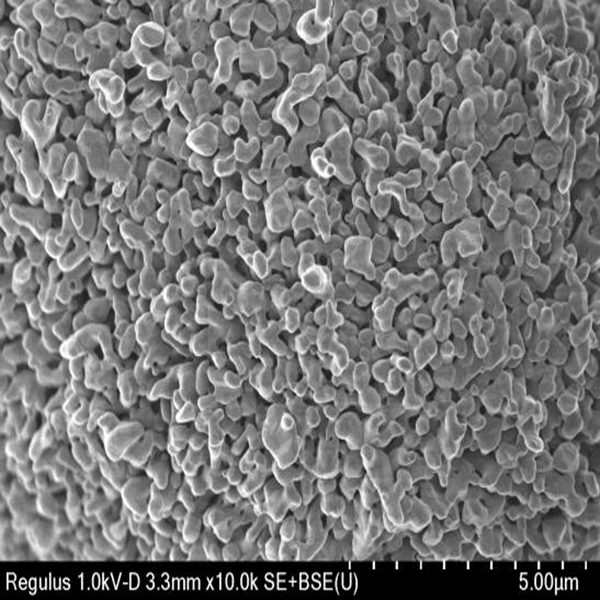

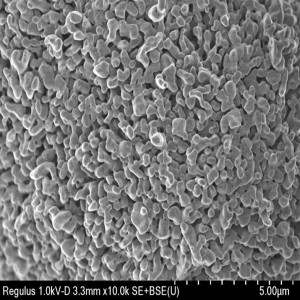

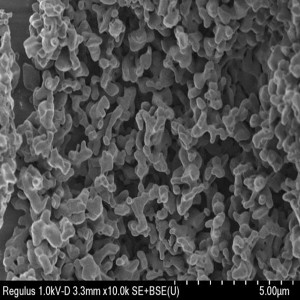

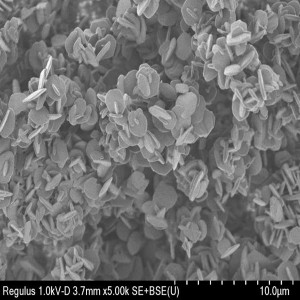

Alumina polish powder

(1)The powder has small particle size and uniform particle size

(2)It has high purity of 99.99% and does not contain mechanical impurities

(3)It has good dispersibility and adsorption to ensure the uniformity and efficiency of the processing process

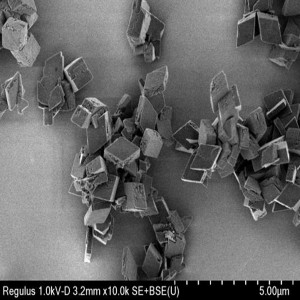

(4)The powder particles have a certain lattice shape and form sharp corners when broken, so as to improve the polishing efficiency;

Our company alumina polish powder technical specifications (OEM avilable)

|

Model |

CX-500 |

CX-600 |

CX-700 |

CX-B1003 |

|

|

Purity |

% |

>99.95 |

>99.95 |

>99.95 |

>99.8 |

|

Phase state |

a-AI2O3 | ||||

|

Appearance |

White powder | ||||

|

Mean Particle Size(D5o) |

um |

0.8-1.2 |

1.3-2.2 |

2.3-3.0 |

1-2 |

|

BET Specific Surface Area |

m2/g |

3-5 |

3 -5 |

3 -5 |

3 -5 |

|

Ca2+ |

PPm |

<30 |

<30 |

<30 |

<500 |

|

Fe3+ |

PPm |

<15 |

<15 |

<15 |

<50 |

|

Cu2+ |

PPm |

<5 |

<5 |

<5 |

<5 |

|

Na+ |

PPm |

<40 |

<100 |

<100 |

<300 |

|

L.O.I |

— |

0.05 |

0.05 |

0.05 |

0.1 |

| Packing | 25kg |

25kg |

25kg |

25kg |

|

1) Metallographic polishing

2) Electronic material grinding

3) Paint polishing

4) 12k-16k mirror polishing

5) Sapphire polishing